How Airports and Transportation Hubs Manage Indoor Air Quality

Airports, train stations, and major transportation hubs are some of the busiest indoor environments in the world. With thousands of travelers passing through every hour, these spaces face unique air quality challenges that typical commercial buildings never encounter. Managing indoor air quality (IAQ) in these high-traffic areas is essential for passenger comfort, staff safety, and compliance with global building standards.

Airports, train stations, and major transportation hubs are some of the busiest indoor environments in the world. With thousands of travelers passing through every hour, these spaces face unique air quality challenges that typical commercial buildings never encounter. Managing indoor air quality (IAQ) in these high-traffic areas is essential for passenger comfort, staff safety, and compliance with global building standards.

In this article, we explore how modern transportation hubs monitor, control, and improve IAQ using data-driven ventilation, chemical management, and advanced sensor technology.

Why IAQ Is a Serious Issue in Airports

Unlike offices or schools, airports face constant and unpredictable environmental pressures:

High passenger density

Crowded waiting areas and security lines lead to:

- Elevated CO₂ levels

- Increased bioaerosols

- Greater humidity fluctuations

Outdoor pollution infiltration

Airports are surrounded by:

- Jet exhaust

- Ground vehicle emissions

- PM2.5 and NO₂ from runways

These pollutants easily enter indoor terminals through doors, ventilation systems, or airside operations.

Large, complex HVAC zones

Airports contain:

- Retail stores

- Gates

- Lounges

- Check-in halls

- Baggage claim areas

Each zone has different ventilation demands, making uniform IAQ control difficult.

Long operating hours

Airports never close, which increases:

- Energy consumption

- Filtration needs

- Maintenance frequency

Continuous IAQ monitoring is essential.

Key Pollutants Airports Must Monitor

Air quality guidelines from WELL, LEED, ASHRAE 62.1, and WHO focus on several core pollutants:

CO₂ (Carbon Dioxide)

Indicates ventilation effectiveness and occupancy load.

PM2.5 & PM10

Common from jet fuel combustion and vehicle activity.

NO₂

Primarily from aircraft engines and transport vehicles.

VOCs

Emitted from:

- Duty-free stores

- Cleaning chemicals

- Airport renovations

- New carpets, furniture, paints

- O₃ (Ozone)

Drifts from outdoor air and impacts respiratory health.

Continuous monitoring of these pollutants is now standard practice in modern transportation hubs.

How Airports Manage and Improve Indoor Air Quality

Advanced Ventilation & Filtration Systems

Airports typically use:

- High-capacity HVAC

- MERV 13–16 or HEPA filtration

- Demand-controlled ventilation (DCV) using sensors

- Pressurization strategies to prevent outdoor infiltration

These reduce PM2.5, NO₂, and odors while keeping CO₂ within safe ranges.

Real-Time IAQ Monitoring Systems

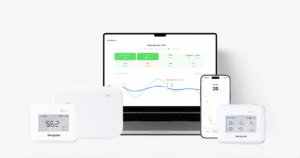

Airports increasingly rely on continuous IAQ sensors, such as Aeropulse Aeronode devices, to measure:

- CO₂

- PM2.5

- NO₂

- Ozone

- VOCs

- Temperature & humidity

Real-time dashboards allow facility managers to:

- Detect pollution spikes instantly

- Adjust ventilation automatically

- Provide transparency to passengers

This supports compliance with WELL Air, LEED v5 IAQ, and RESET Air standards.

Zonal IAQ Control

Different areas of airports need different IAQ strategies:

- Zone, IAQ Challenge, Solution

- Check-in halls, High CO₂ & humidity, DCV + real-time CO₂ monitoring

- Security lines, Close-contact exposure, Increased airflow & HEPA

- Boarding gates, High PM during aircraft taxiing, Pressurization & PM sensors

- Lounges, VOCs from materials, Low-VOC furniture + VOC monitoring

- Baggage claim, Outdoor infiltration, High-capacity filtration

This ensures stable air quality across the entire terminal.

Use of Low-Emission Materials

Airports often incorporate:

- Low-VOC paints

- Formaldehyde-free furniture

- Cleaners certified for low chemical emissions

This reduces indoor VOC buildups.

Public-Facing Air Quality Dashboards

Some airports now display real-time IAQ screens showing:

- CO₂

- PM2.5

- Temperature

- Humidity

This boosts public trust and positions airports as health-conscious facilities.

Case Study: How a Mid-Size Airport Improved IAQ During Peak Travel Season

A medium-sized international airport in Southeast Asia faced recurring IAQ problems during high-travel months:

Challenges Identified

- PM2.5 spikes near boarding gates during aircraft taxiing

- High CO₂ levels in immigration and security areas

- VOC buildup in newly renovated retail zones

- Complaints from staff about fatigue and headaches

Aeropulse Deployment

Aeropulse Deployment

The airport installed Aeronode A100 (multi-gas) and A200 CO₂ sensors across 42 critical points, including:

- Gates

- Immigration

- Lounges

- Duty-free shops

- Baggage claim

All sensors send real-time data to the Aeropulse IAQ Dashboard.

Insights Discovered

Insights Discovered

Aircraft pushback caused PM2.5 spikes every 12–20 minutes

Immigration halls had CO₂ levels exceeding 1,400 ppm during peak hours

VOC spikes occurred at night after cleaning and floor polishing

Two ventilation units were underperforming

Actions Implemented

Automatic ventilation boosts triggered by PM2.5 and CO₂ thresholds

Adjusted cleaning schedules to low-occupancy hours

Pressurization changes for gates facing the runway

Maintenance on faulty ventilation units

Conclusion

Airports and transportation hubs face unique IAQ challenges due to large crowds, outdoor pollution, and continuous operation. Leading facilities now rely on:

- Real-time IAQ monitoring

- Advanced ventilation and filtration

- Zonal IAQ control

- Low-VOC materials

- Data-driven facility management

With solutions like Aeropulse A100 and A200, airports gain precise insights that help reduce pollution exposure, improve comfort, and support certifications such as WELL, LEED v5, and RESET Air.